PRODUCTION provided in progress!

The end of the year had been very productive, the production at the beginning of the year is also getting off to a good start! In fact, in parallel with the industrial activity which is doing well, this month we are assembling 4 chassis dynamometers for France and Italy. Thus our seven production sites allow us to respond under the best conditions to short-term projects as well as to projects requiring a longer development.

We thus have in the planning 1 industrial HUBSCAN, 2 EASYSCAN and 2 AUTOSCAN in the program.

Unlike the majority of our competitors, the ROTRONICS technical teams specifically calibrate each bench (inertia and strain gauge) and a vehicle is systematically passed over it.

Beyond the fine balancing of the rollers which is carried out in our workshops, we measure the level of vibration once the bench is fully assembled, which guarantees you a maximum noise level unmatched on the market. (unlike competing benches often mounted rigid). No doubt your neighbors will appreciate it!

All these steps on which we do not compromise guarantee the measurement accuracy as well as the immediate activation of your bench after delivery / installation.

The AUTOSCAN rolls in our stock are just waiting for your order.

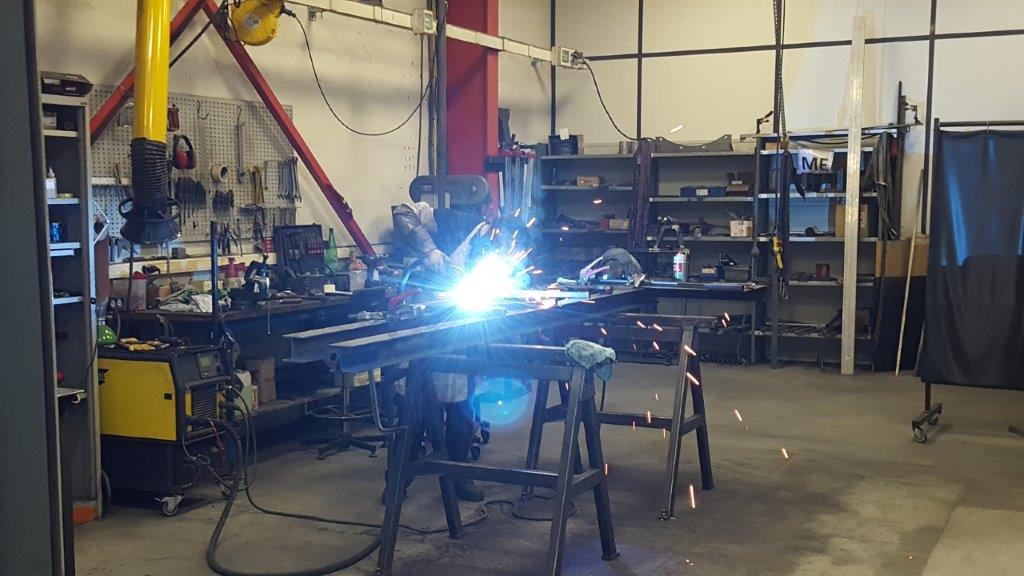

Standard or custom production, our boilermaking workshop responds to all your specific requests.

INDUSTRY

We are in the process of making a tractor / truck bench for an industrial client. you will know more quickly.

4-wheel drive bench with 2M diameter rollers and more than 30000N.m on the axle !!

More news to come. Do not hesitate to follow us on FACEBOOK, INSTAGRAM and LINKED IN.

AT YOUR SERVICE

We are at your disposal for all your vehicle, engine or component test bench projects.

Do not hesitate to contact our sales teams who will help you define the right solution for your needs.

Rotronics wishes you to achieve all your goals for this year 2019 !!